-

tel:

+86 18168939059 -

email:

sunny@wafullwater.com

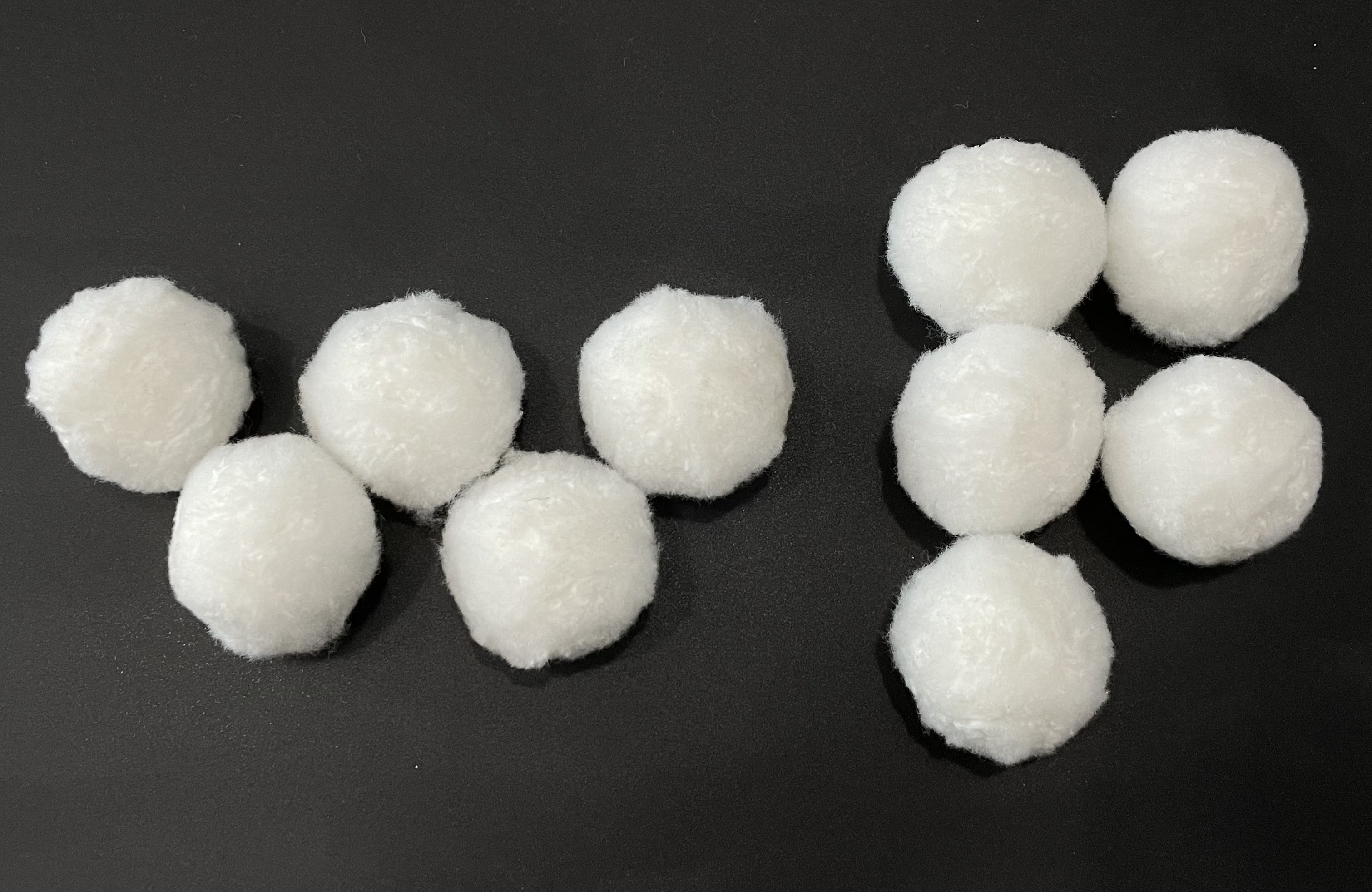

Fiber Ball uses high-quality polypropylene fiber and polyester fiber as raw materials. Because it uses a large number of biological groups attached to its surface and oxygenates, and repeatedly contacts with sewage, it can intercept and degrade small suspended solids that are not easy to precipitate and remove, so as to achieve the purpose of purification. The filtration speed is 4-4.5 times higher than that of quartz sand. It is easy to backwash and regenerate, and it can realize automatic management. Generally, the filtration speed is 35m / h, the inlet water of primary filtration is 120mg / L, the outlet water SS is ≤ 5mg / L, the inlet water of fine filtration is 25mg / L, and the outlet water is ≤ 2mg / L. because of its special technology, it can be quickly replaced and maintained. At present, it is widely used in high standard water use, circulation, side filtration, and waste water recovery and utilization in power, oilfield, chemical, metallurgy, electronics and other industries,swimming pool.

The adsorption capacity of oil and organic compounds on the surface of high-efficiency modified fiber ball was enhanced after modification. A new type of binding method of modified fiber ball, the porosity of filter layer decreases gradually along the direction of water flow during operation, forming a relatively ideal pore distribution state on the filter material with large size and small size, and better filtering effect.

|

Model |

Filter fiber ball |

|

Size |

30mm,40-50mm,50-60mm |

|

material |

100% polyester, polypropylene or acrylic fiber |

|

Density |

1.38 g/cm³ |

|

Filling density |

70-90 kg/m³ |

|

Filtration speed |

20-85 m/h |

|

Strength |

4-6 g/D |

|

Specific surface area |

3000m²/m³ |

|

Porosity |

96% |

|

Sunlight resistance |

Excellent |

The specific advantages of filter fiber ball :

1.Flexible media can be compressed and reduced easily;

2.The ideal filter layer is loose and dense;

3 Moderate specific gravity, easy back washing and less water consumption;

4.Chemical fiber material is wear-resistant and corrosion-resistant;

5.It has strong adaptability and wide application;

6.High filtration rate without adding medicine;

7.Compact equipment, small footprint, high efficiency.

.png?x-oss-process=image/resize)