-

tel:

+86 18168939059 -

email:

sunny@wafullwater.com

Swirl aerator

The liftable swirl aerator is a new type of high-efficiency aeration device, which is mainly composed of four parts: the outer cylinder, the air intake pipe, the back flow plate and the wedge-shaped structure. The whole is made of nylon 66+glass fiber (PA66+GF) material Manufactured, with super mechanical properties and corrosion resistance. The device is easy to install, and supports online installation, without the need for users to clean the pool or stop production; at the same time, the device also has high dissolved oxygen efficiency, small pressure loss, strong stirring force, no clogging, no silt accumulation at the bottom of the pool, maintenance-free, Absolute advantages such as intermittent operation and long life; judging from the years of use by thousands of enterprise users at home and abroad,

Our factory's liftable swirl aerator is mainly suitable for the construction of various municipal sewage, printing and dyeing waste water, chemical waste water, coal chemical waste water, paper making waste water, starch waste water, alcohol waste water, bean product waste water, food processing waste water and other sewage treatment plants. Aeration systems for expansion projects and renovation projects for old aeration tanks. The advantages are more obvious in high-salt, high-oil, high-hardness, and easy-to-scale waste water. The microporous aerator can be completely replaced without changing the original main pipeline. The installation time is short, saving 60% of the construction period.

When working, the air is sprayed into the bottom of the aerator at high speed from the intake pipe, and the air whose specific gravity is much smaller than that of water will rise rapidly with great momentum, and negative pressure will be generated inside the aerator, and the active pollutants at the bottom of the pool are about 1.5 times the air volume. The mud and sewage are sucked into the aerator to realize the secondary mixing; the mixture of air, activated sludge and sewage will generate a violent vortex flow through the rotary cutter during the high-speed rising process to realize the second mixing; the mixture is then passed through a specially designed multi-layer The cutter is crushed into micro-particle groups, and the oxygen is forced to dissolve into the water to realize the third mixing; the oxygen-enriched mixture is ejected from the aerator cylinder at a high flow rate, so as to achieve uniform mixing in the pool.

(1) Special structure, never clogging: During operation, due to the large flow rate of compressed air, the gas-liquid mixer will not cause clogging. Suitable for all high concentration wastewater treatment ponds.

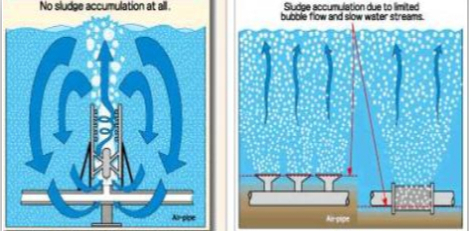

(2) Strong stirring power and no silt accumulation: a strong mixing and stirring effect is formed in the entire aeration tank, keeping the activated sludge in a suspended state all the time, and at the same time making no silt accumulation at the bottom of the aeration tank.

(3) Small pressure loss, low energy consumption, energy saving: very small pressure loss, under the premise of the same air supply volume, the energy consumption of the fan is low. Year-round operation without clogging, no attenuation of dissolved oxygen efficiency, and no sludge accumulation; high efficiency and energy saving (over 25% power saving), and a single aeration area of 6-10㎡;

(4) Maintenance-free, long life: The gas-liquid mixer has no moving parts, is durable, requires no maintenance, and has a service life of more than 10 years.

(5) Stable performance: the oxygen supply capacity will not decay with the increase of use time, and the stable DO value in the pool has been maintained.

(6) There is no need for fixed installation at the bottom of the pool, and the maintenance is very convenient. There is no need to clean the pool or stop production, and it can be installed online.

|

Material |

Nylon |

Ventilation air volume |

35-45m³/h |

|

Oxygen utilization |

15%-18% |

Pressure loss |

0.5-1.5pa |

|

Service Area |

4-10㎡ |

Suitable water depth |

>3m |

|

Sludge concentration |

60000mg/I |

Service Life |

15 years |

|

Working temperature |

0-80℃ |

Application |

Municipal sewage, industrial sewage, MBR system |

- The swirl aerator will not be blocked in the perennial operation, the dissolved oxygen efficiency will not be attenuated, and there will be no sludge accumulation;

- The high-efficiency swirl cyclone aerator is efficient and energy-saving, saving at least 25% of electricity;

- The high-efficiency swirl cyclone aerator does not need to be fixedly installed at the bottom of the pool, the maintenance is very convenient, and the service life is more than 15 years;

- The replacement is simple, the swirl cyclone aerator does not need to change the original main pipeline, and the microporous aerator can be completely replaced;

- The high-efficiency cyclone aerator has the effect of lifting mud and water, and there will be no sludge deposition at the bottom of the pool. The high-speed water flow breaks the sludge mass, improves the activity of microorganisms, and promotes the decomposition of organic matter by microorganisms.

Longer service life

- The product is made of imported classic materials: nylon + glass fiber. The material is special ingredient, which increases the toughness of the product while retaining sufficient strength.

- According to project feedback, strength the stressed parts and vulnerable structures of the product.

- Special production process, accurate control of mold temperature, injection pressure and other conditions, increase the toughness strengthening process.

Product use and advantages:

Applicable to various municipal sewage, printing and dyeing wastewater, chemical wastewater, coal chemical industry water, papermaking wastewater, starch wastewater, alcohol wastewater, bean product wastewater, food processing wastewater and other sewage treatment plants for new expansion projects and old aeration tank renovation projects Gas system has more obvious advantages in high-salt, high-oil, high-hardness, and easy-to-scale wastewater. The microporous aerator can be completely replaced without changing the original main pipeline. Short installation time; save 60% construction period.

Schematic photos of the installation site:

.png?x-oss-process=image/resize)